Machine Details Images

Punching plate

Punching plate NO.46 Oil

NO.46 Oil Start Switch

Start Switch Punching distance

Punching distance Oli Box

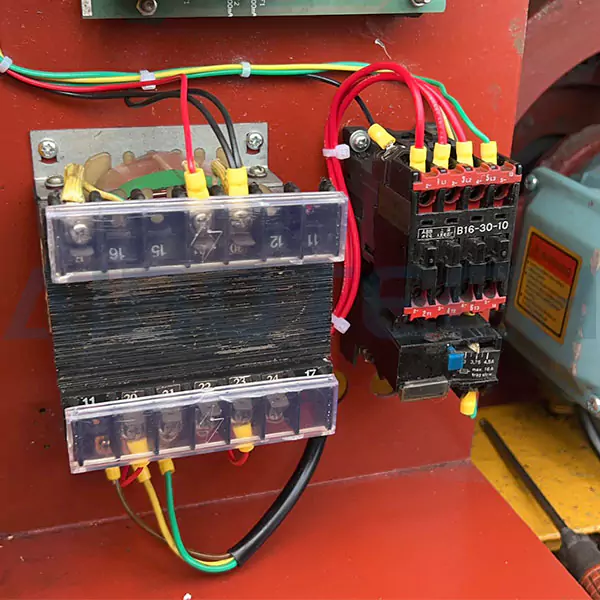

Oli Box Electric part

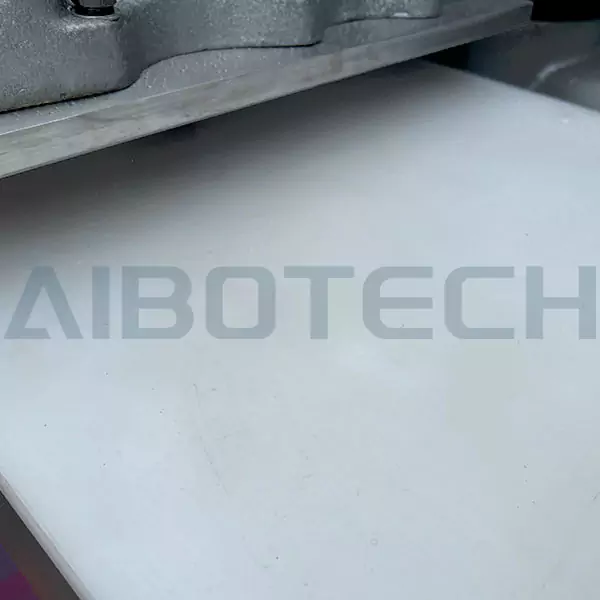

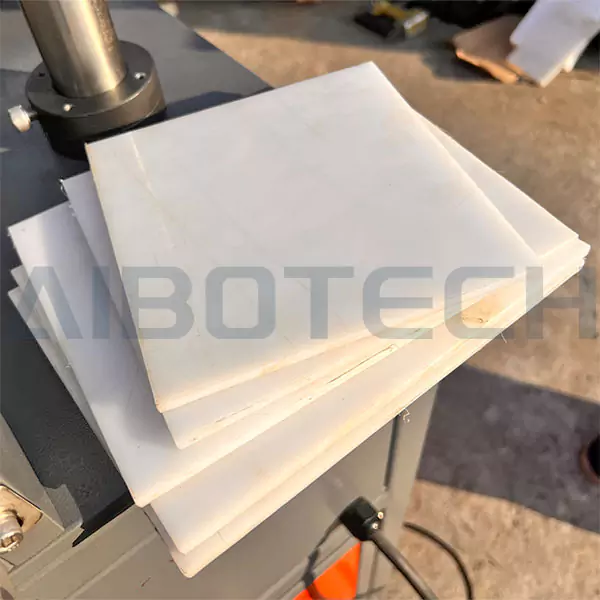

Electric part Nylon Plate

Nylon Plate

Adjust button

Adjust buttonMachine Accessories Images

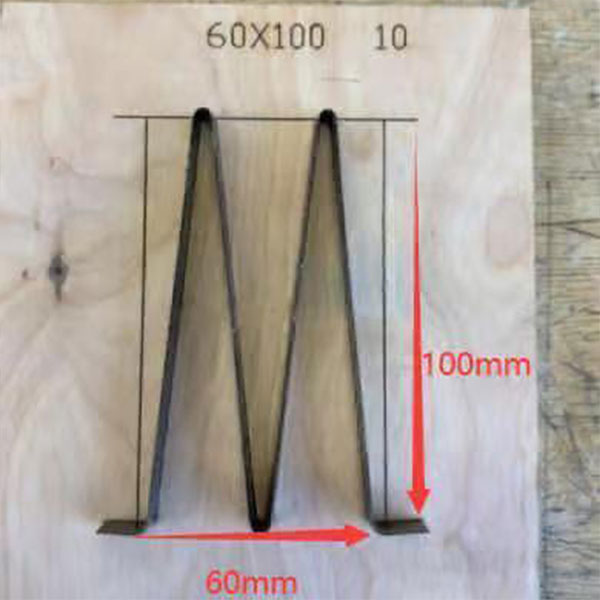

Punching Board -- 2pcs free

Punching Board -- 2pcs free Punching Board -- 2pcs free

Punching Board -- 2pcs free Punching Board -- 2pcs free

Punching Board -- 2pcs free Punching Board -- 2pcs free

Punching Board -- 2pcs free Nylon plate -- 5pcs free

Nylon plate -- 5pcs freeAppreciation of Timing Belts

Machine Videos

Why do we punch finger before belt joint?

Notching a conveyor belt (i.e., cutting a zigzag or stepped pattern at the splice area) before splicing is primarily done to enhance splice strength, improve bonding effectiveness, and ensure flexibility and durability at the joint. The specific reasons are as follows:

1.Increased Bonding Area for Higher Splice Strength

Notching transforms the splice surface from flat to a zigzag or stepped shape, significantly increasing the bonding area.

Adhesive or vulcanizing material can better fill the notches, creating a stronger mechanical interlock and reducing reliance solely on adhesive strength.

Ideal for high-tension, heavy-load belts (e.g., steel cord belts in mining or port applications).

2.Distributes Stress, Reducing Splice Failure Risk

Flat splices concentrate stress at the edges, leading to peeling or cracking.

A notched splice distributes stress across multiple teeth, preventing localized stress points and extending splice life.

3.Improves Flexibility, Reducing Wear During Operation

A notched or stepped splice is more flexible than a straight splice, allowing better adaptation to bending over pulleys.

Reduces fatigue or delamination caused by repeated flexing.

4.Compatibility with Different Splicing Methods

Vulcanized Splices: Stepped notching improves vulcanization, allowing rubber to penetrate fully for a uniform bond.

Mechanical Splices: Some mechanical fasteners (e.g., bolt hooks) require notching for better grip.

Machine Parameters

| Model | GSB-2C |

| Blanking force | 20T |

| Stroke range | 20~140mm |

| Power of Motor | 1.5KW |

| Cutting area | 1000*500mm |

| Machine Size | 950*1000*1380mm |

| Voltage | 1PH 220V / 3PH 380V |