Machine Details Images

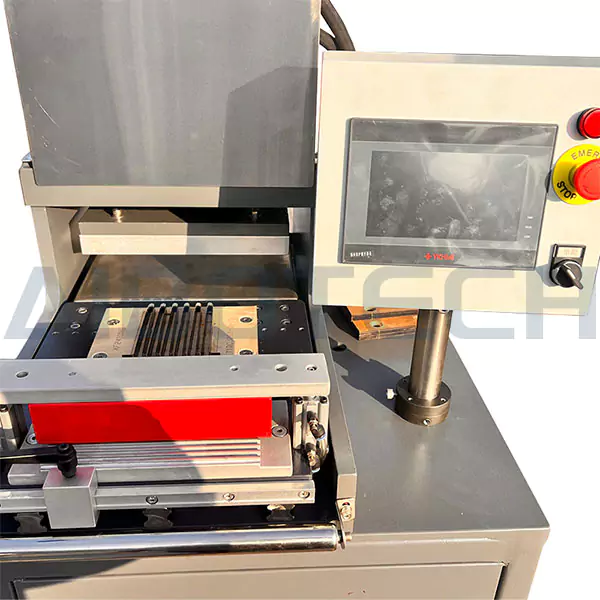

Working plate

Working plate Punching plate

Punching plate Punching plate

Punching plate Oil pipe

Oil pipe control panel

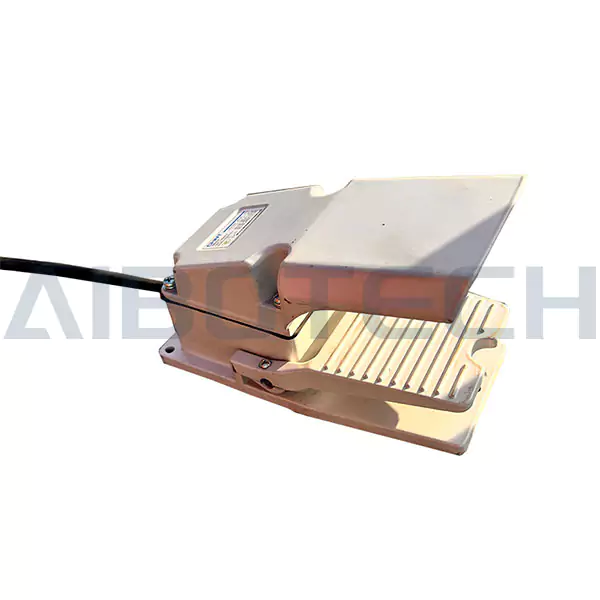

control panel foot switch

foot switch cylinder

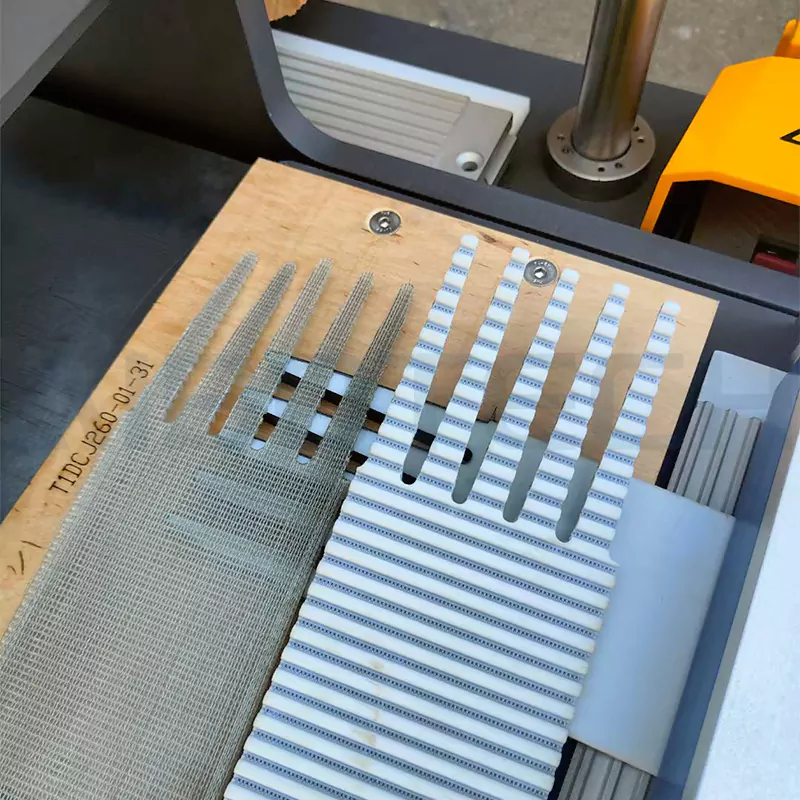

cylinder timing belt mould

timing belt mould cutting board

cutting board power wire

power wire plate

plate hydro-cylinder

hydro-cylinderMachine Accessories Images

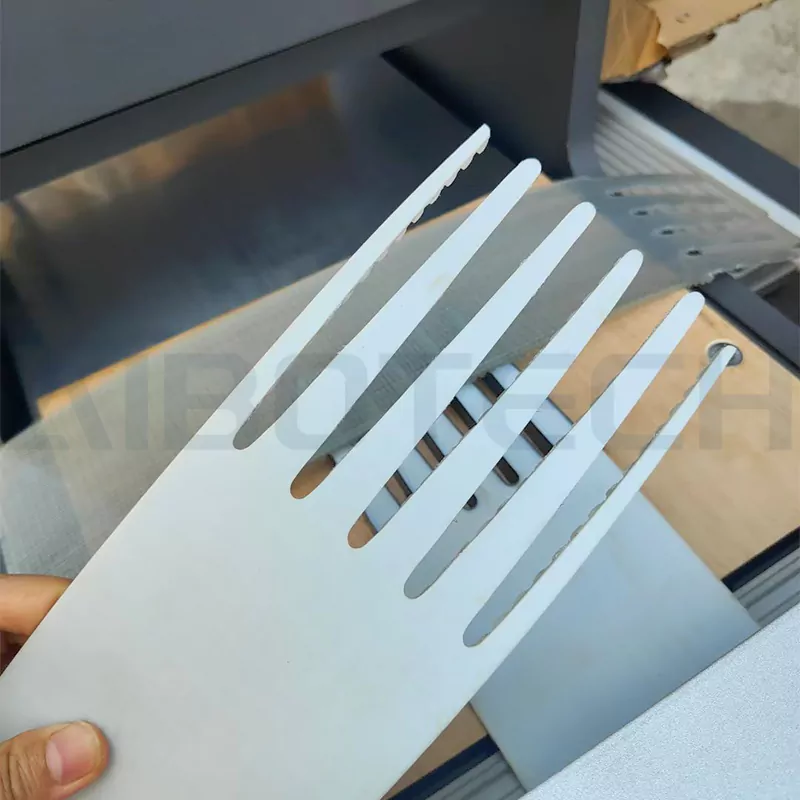

Cutting board -- 2pcs free

Cutting board -- 2pcs free Cutting board -- 2pcs free

Cutting board -- 2pcs free Nylon Plate -- 5pcs free

Nylon Plate -- 5pcs free Cutting board -- 2pcs free

Cutting board -- 2pcs free Cutting board -- 2pcs free

Cutting board -- 2pcs freeAppreciation of Timing Belts

Machine Videos

Why Are Industrial Belt Joints Serrated (Notched)?

Serrated (or notched) joints in industrial belts are designed to enhance the strength, durability, and operational stability of the splice. Here are the key reasons and advantages:

1. **Increased Contact Area for Better Bonding Strength**

- Serrations create interlocking teeth that provide more surface area for adhesive (e.g., glue) to bond, forming a mechanical interlock after curing.

- This structure resists peeling and shearing forces better than a straight-cut joint, reducing the risk of splice failure.

2. **Distributes Stress, Reducing Localized Wear**

- The joint is a stress concentration point during operation. A serrated pattern spreads stress across multiple tooth surfaces instead of a single line, extending splice life.

- Particularly beneficial for high-tension, high-speed, or frequent start-stop applications.

3. **Improved Flexibility for Belt Bending**

- The teeth allow slight elastic deformation when the belt passes over pulleys or rollers, reducing rigid-edge wear and preventing delamination or cracking.

4. **Prevents Misalignment**

- The interlocking teeth help resist lateral displacement (e.g., from belt tracking issues), maintaining splice alignment.

5. **Compatibility with Special Belt Types**

- For multi-ply fabric belts (e.g., EP, NN) or steel cord belts, serrations enable staggered layer bonding, preventing simultaneous ply separation.