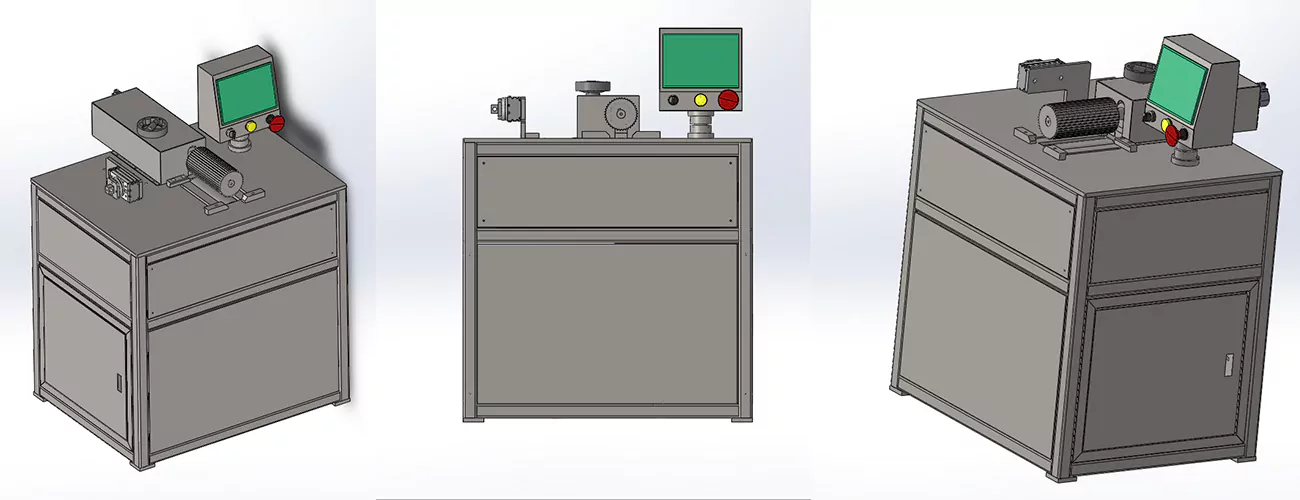

Machine Details Images

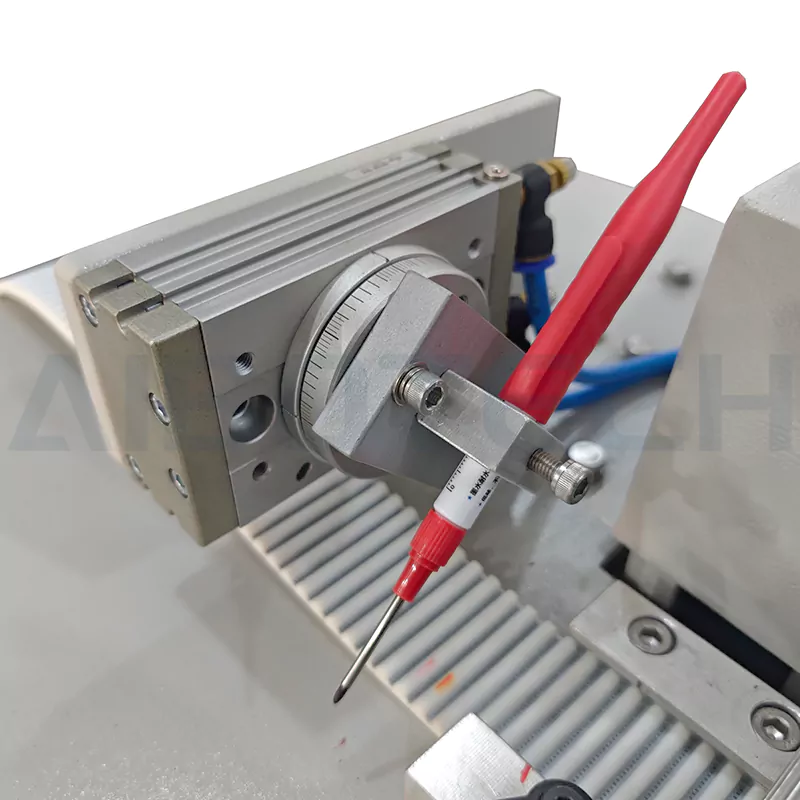

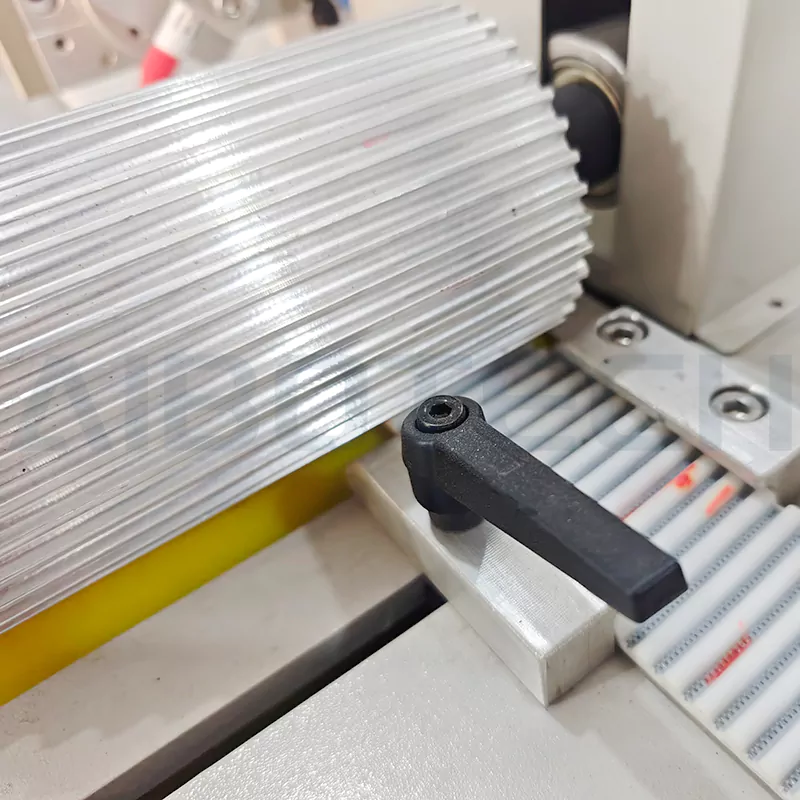

Working Panel

Working Panel Mark Pen

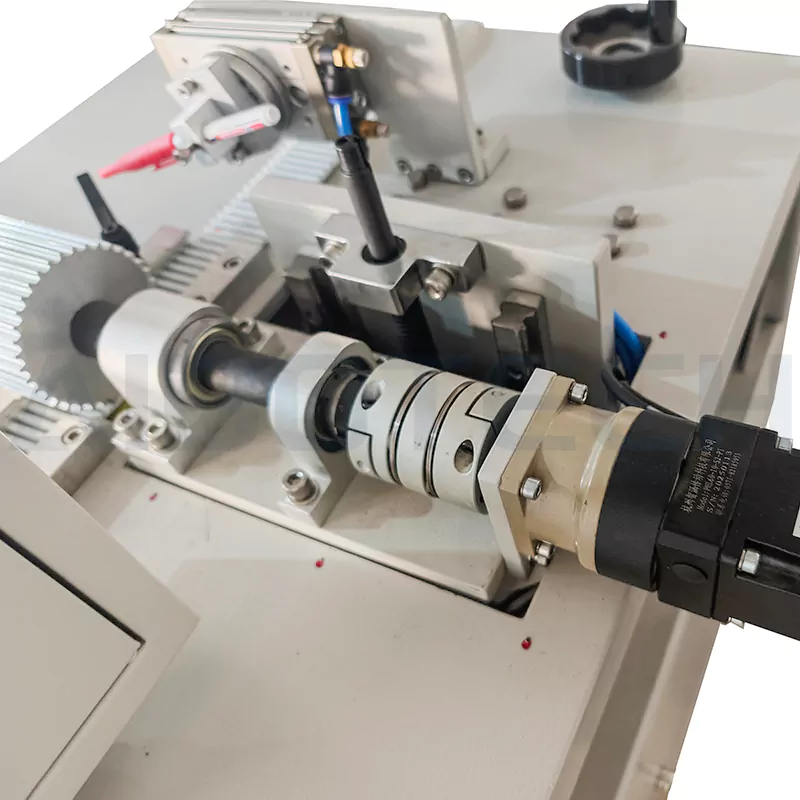

Mark Pen driving system

driving system 7

7 6

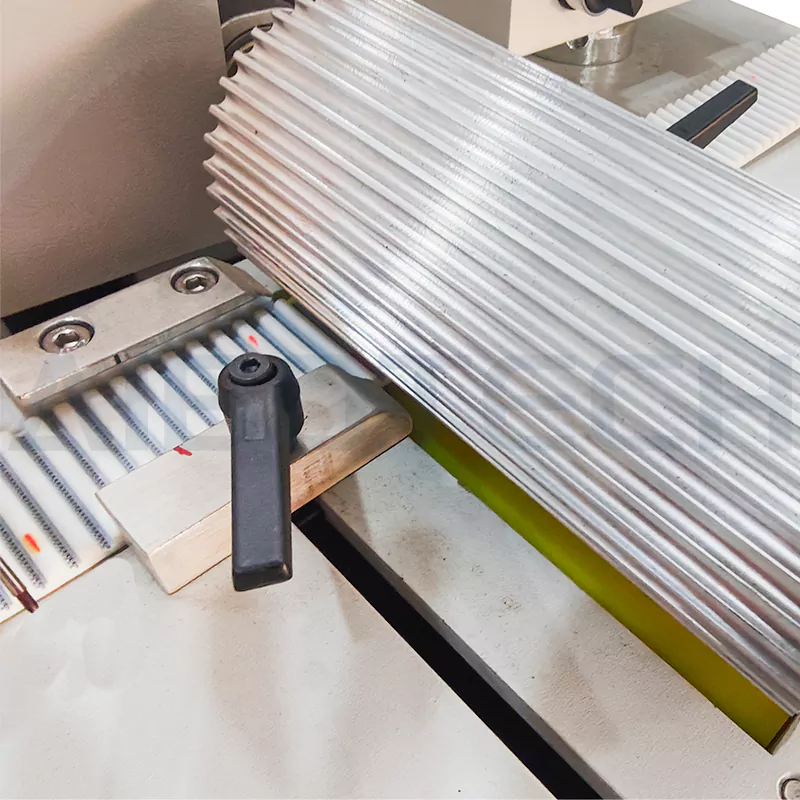

6 3

3 2

2Machine Accessories Images

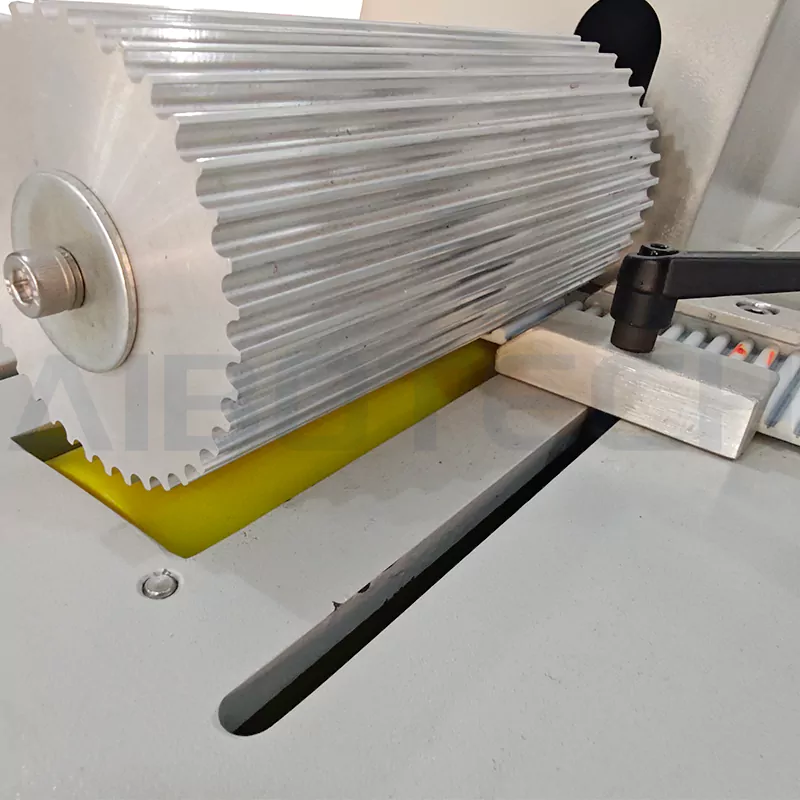

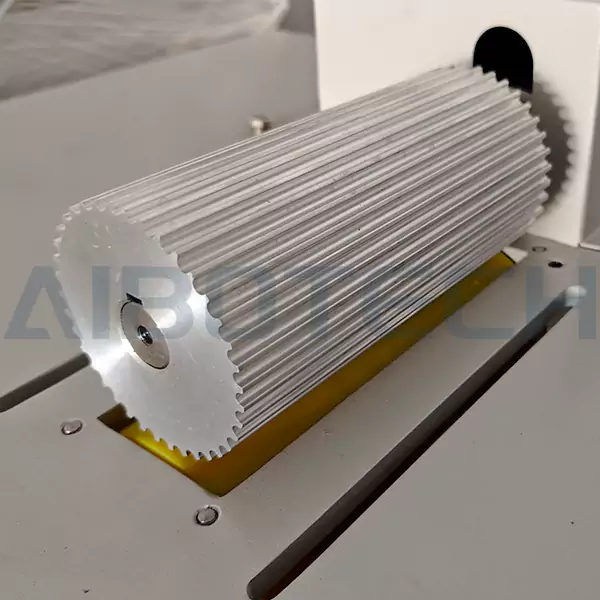

Timing Pulley

Timing Pulley Timing Pulley

Timing Pulley Timing Pulley

Timing PulleyAppreciation of Timing Belts

Machine Videos

Why do we need this tooth counting machine?

The number of teeth affects the circumference of the belt, which in turn affects the transmission speed (linear speed = rotational speed × circumference). In high-speed scenarios, you need to choose a belt with the right number of teeth to avoid resonance or noise.

The timing belt transmits power through the meshing of the belt teeth and the pulley. The number of teeth directly determines the accuracy of the transmission. By matching the fixed number of teeth, the speed of the input shaft and the output shaft can be strictly synchronized to avoid slippage (compared with ordinary belt transmission).

Features

1.High Precision Counting

Optical sensors, laser scanning or mechanical probe technology can quickly identify and count the number of teeth on the synchronous belt with extremely small errors (usually within ±1 tooth).

Suitable for synchronous belts of different pitches (such as MXL, GT2, HTD, etc.) and materials.

2.Automated Operation

There is no need to manually count teeth one by one. Rapid scanning can be achieved through automatic conveyor belts or rotating mechanisms, greatly improving efficiency (such as detecting dozens of teeth per second).

3.Tooth defect detection

It can simultaneously detect defects such as missing teeth, tooth wear, cracks, deformation, etc. to ensure the quality and transmission reliability of the synchronous belt.

4.Strong compatibility

It can adapt to synchronous belts of different widths, thicknesses and tooth shapes (such as arc teeth, trapezoidal teeth, etc.), and can be flexibly switched by replacing the fixture or adjusting the sensor parameters.

5.Data recording and analysis

Built-in software records inspection results (e.g. number of teeth, defect location) and supports report generation or connection to a production management system (MES).

Benefits

1.Improved efficiency

Manual tooth counting is time-consuming and error-prone, while tooth counting machines can complete counting in a few seconds, which is suitable for mass production or quality inspection scenarios.

2.Reduced human errors

Avoids the problem of missing and repeated counting during manual counting, especially for long synchronous belts (such as hundreds of teeth).

3.Quality control

Through the defect detection function, defective products can be eliminated in advance to reduce the risk of equipment downtime caused by synchronous belt failure.

4.Cost savings

In the long run, reduce labor costs, rework costs and after-sales maintenance costs.

5.Standardization support

Ensure that the number of synchronous belt teeth meets international standards (such as ISO 5296) to meet high-precision transmission requirements.

Machine Data Sheet

| Item Model | SC200 |

| Power | 400W |

| Voltage | 1PH 220V,50hz or 60hz |

| Control Method | PLC control |

| Machine Size | |

| Machine Weight | |

| Packing Size |

Typical application scenarios

Timing belt manufacturers: tooth number verification and defect screening before delivery.

Equipment maintenance department: quickly confirm whether the number of teeth of the replacement timing belt matches.

Automation equipment integration: scenarios such as robots and conveyor lines that require regular maintenance.

Selection considerations

Accuracy requirements: Select a sensor with appropriate resolution according to the pitch and tolerance of the synchronous belt.

Detection speed: High-speed production lines need to match fast scanning models.

Software functions: Whether it supports data export or is compatible with existing systems.

Environmental adaptability: Dust-proof and oil-proof design (suitable for industrial sites).

Summary

The synchronous belt gear counting machine solves the pain points of manual operation through automation, high precision and multi-functional detection, significantly improves production efficiency and product quality, and is especially suitable for industrial fields with strict requirements on transmission reliability.

Drawings & Dimensions

Our engineering team can provide tailored designs to meet specific project requirements.

FAQ

1.Is this machine necessary?

-- We can also do manual calculations, but when working in batches, if you have this machine, it will save you a lot of manual calculation work and save you labor costs.This is the greatest significance of automated machines,

2.Machine voltage?

-- 1PH 220V ,50 or 60HZ.

3.Lead time?

-- it would take 15days to produce,If there are special circumstances, we will explain them to you first.

4.Machine warranty?

-- 1years for the whole machine .

5.Will the timing pulley fit my belt?

-- We produce the timing pulley according to your belts. if you have special requirment ,please feel to contact us.