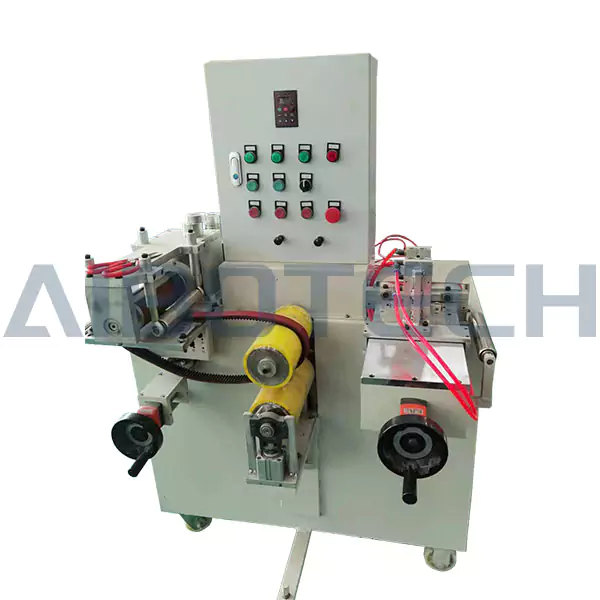

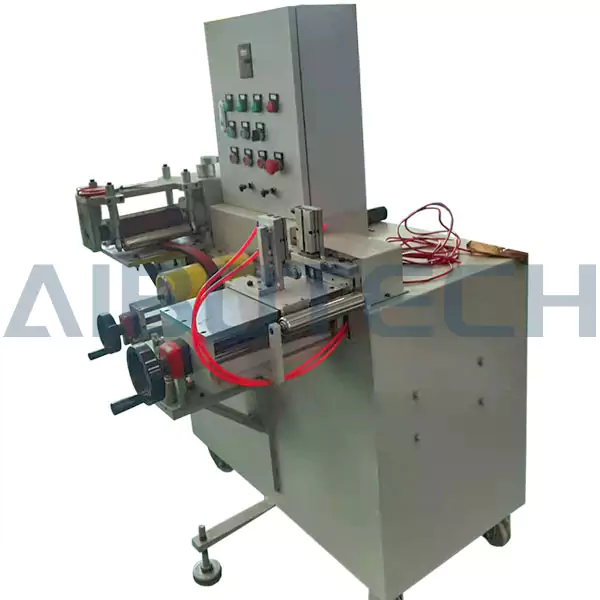

Machine Details Images

Entire Machine

Entire Machine Electrical Part

Electrical Part Machine Side

Machine Side Entrance

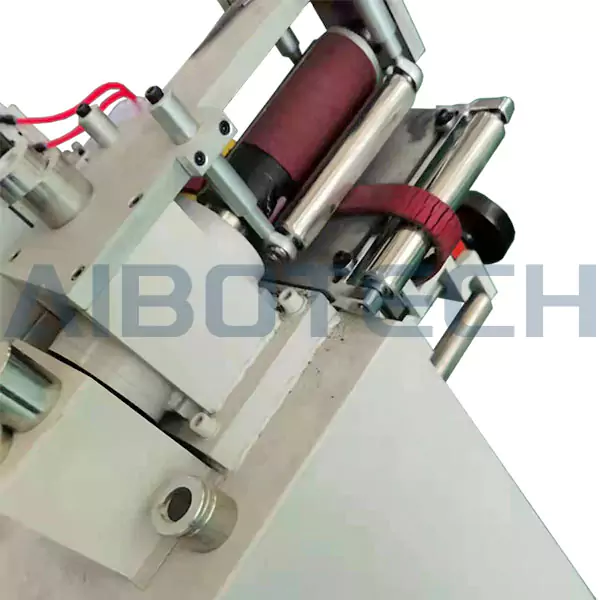

Entrance Belt Clamp and Belt Grinder

Belt Clamp and Belt GrinderMachine Accessories Images

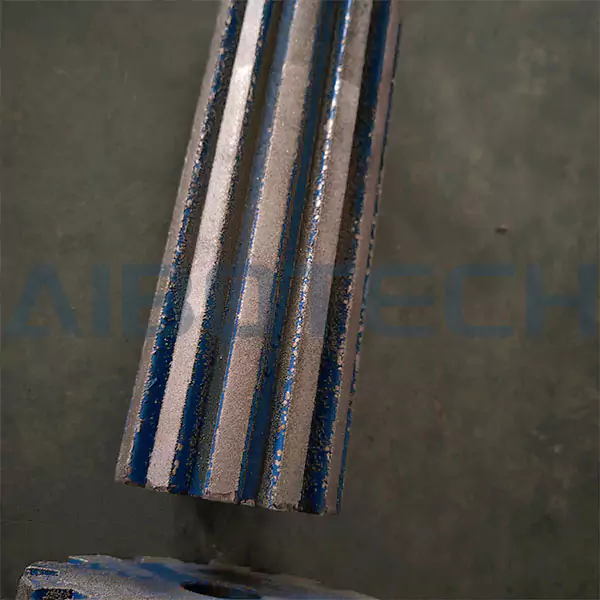

Surface Grinder

Surface Grinder Edge Grinder

Edge Grinder Entire Grinder

Entire GrinderAppreciation of Timing Belts

The function of edge grinding

1.Reduce edge wear

Timing belts may come into contact with guide rails, baffles, or other mechanical components during operation, and sharp edges are prone to friction and wear. Smooth edges after grinding, reducing frictional resistance and avoiding fiber delamination or cracking at the edges.

2.Prevent chip shedding

Unpolished edges may generate debris due to long-term friction, contaminate equipment, or get stuck in meshing areas. Grinding edges can reduce such risks.

3.Improve meshing accuracy

For high-precision transmissions such as robots and CNC machine tools, edge grinding can ensure that there is no interference between the belt teeth and the belt wheel during meshing, resulting in smoother operation.

The role of grinding (surface treatment)

1.Enhance anti adhesion

Grinding treatment can reduce the adhesion of foreign objects (such as dust and oil stains) on the surface of the belt in humid, dusty, or oily environments, avoiding slipping or accelerated wear.

2.Improve friction coefficient

Some working conditions require specific friction characteristics (such as anti-static and high friction transmission), and the surface roughness of the grinding surface can be adjusted to meet the requirements.

3.Remove burrs

After the synchronous belt is formed, there may be small burrs on the surface. Grinding can prevent burrs from damaging the pulley or other components.

Why do we need to do edge grinding and surface grinding?

High speed transmission: Grinding reduces air resistance and edge vibration, and grinding reduces noise during high-speed operation.

Strict environment: In industries such as food processing and pharmaceuticals, grinding edges and surfaces can meet hygiene requirements (easy to clean, residue free).

Long lifespan requirements: such as automated production lines, significantly extending the replacement cycle of synchronous belts through polishing treatment.

Coating Work: Treat the surface of the belt in preparation for applying adhesive to the belt.