Machine Details Images

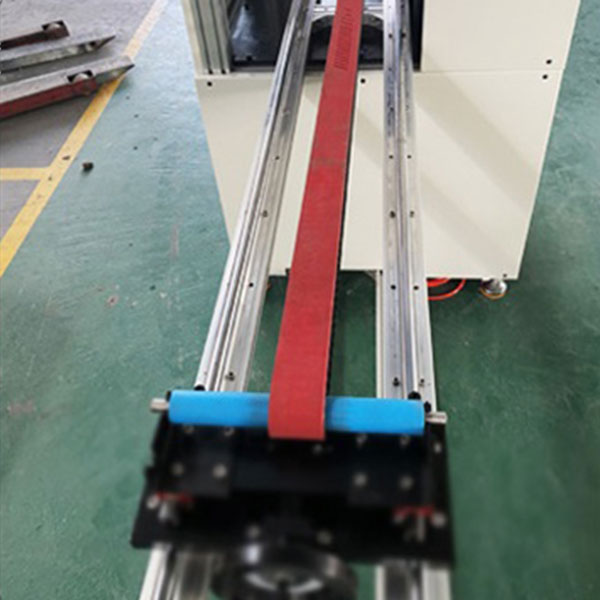

Tensioning device

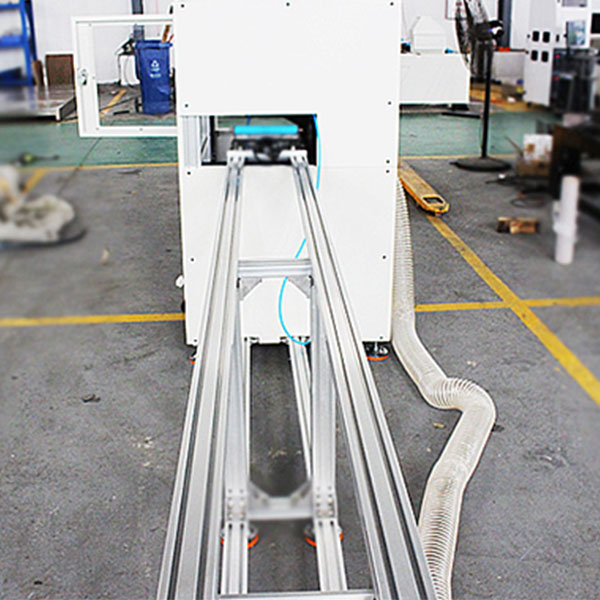

Tensioning device Tracking Rail

Tracking Rail 1

1 2

2 3

3 6

6 4

4 5

5 8

8 14

14 15

15 7

7 9

9 11

11 12

12 13

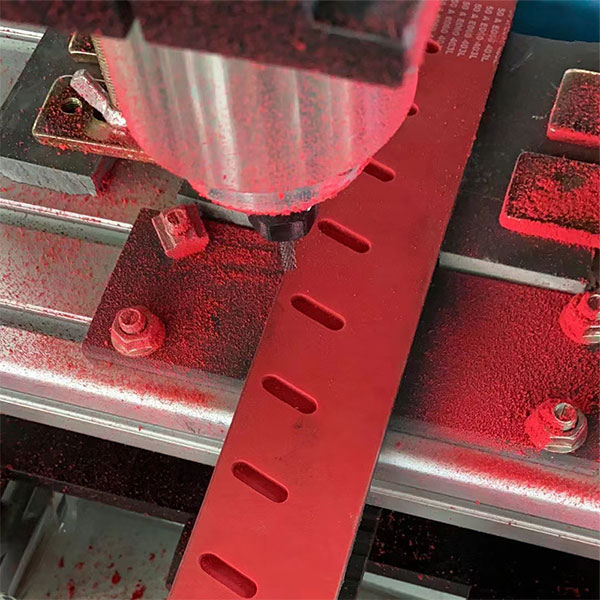

13Machine Accessories Images

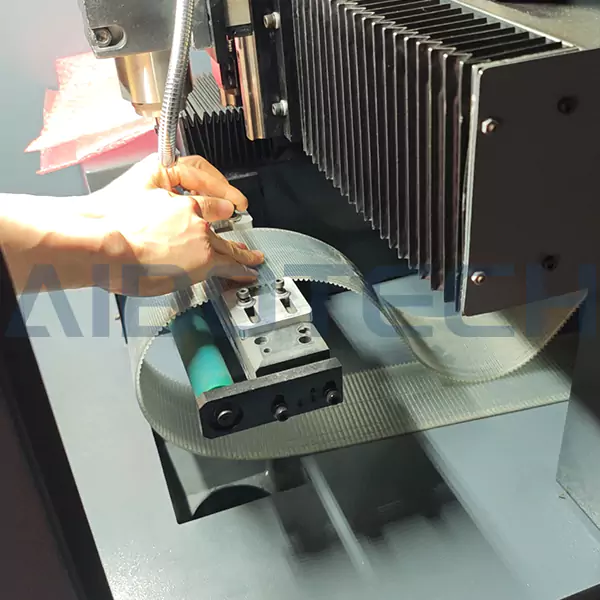

Blade

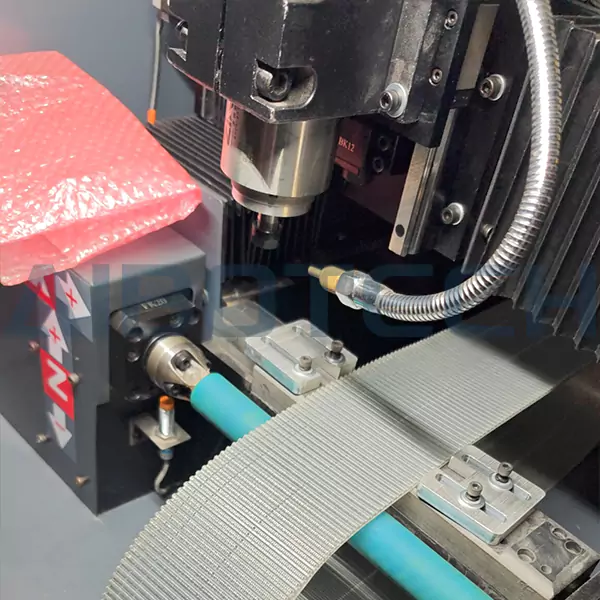

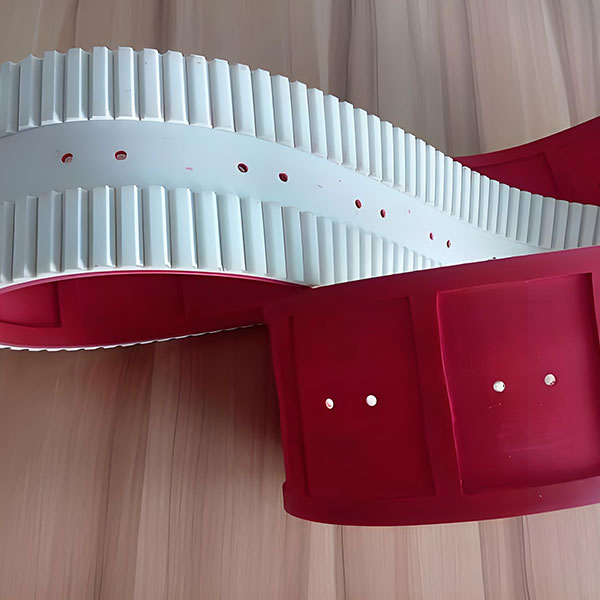

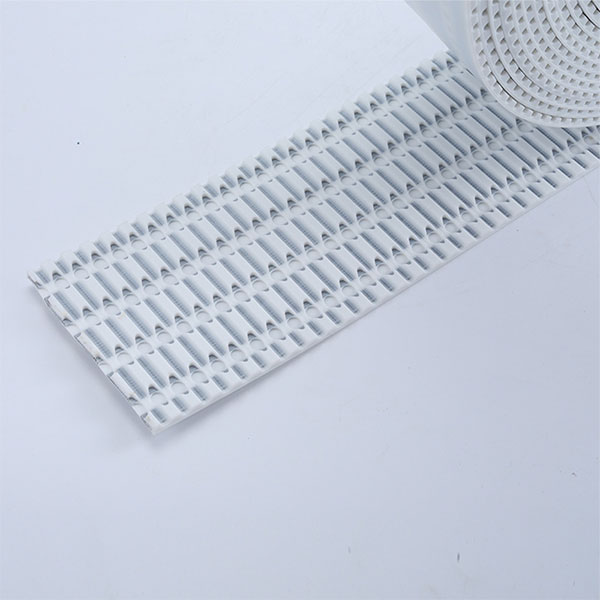

BladeAppreciation of Timing Belts

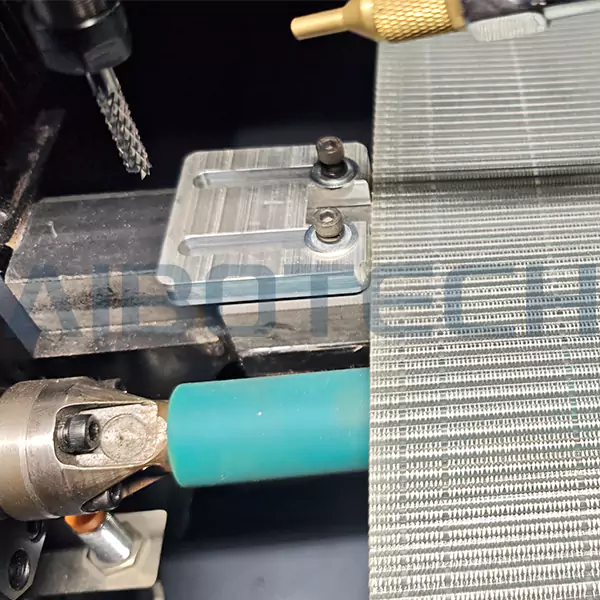

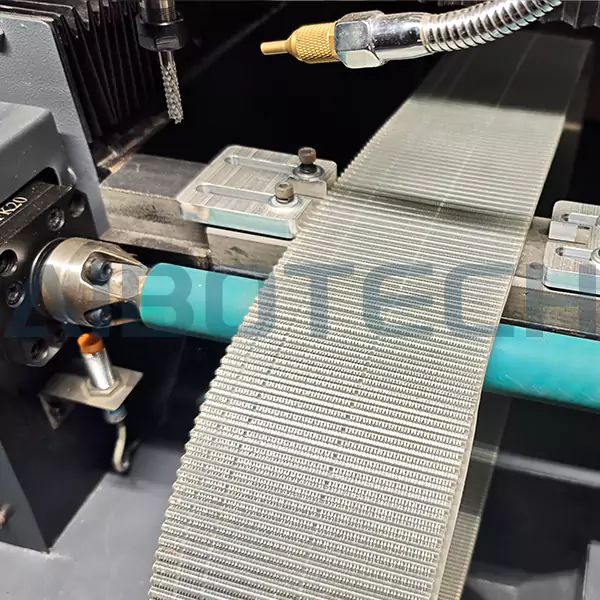

Perforating Work On The Timing Belt

Timing belt perforating refers to punch holes of specific shapes and positions on the timing belt to meet special transmission or installation requirements.

What kind of holes can we make and what are their uses?

Mounting holes - used to fix timing belts or connect other components

Ventilation holes - improve heat dissipation performance

Positioning holes - used for precise positioning or detection

Specially shaped holes - meet specific mechanical needs

What is the punching method of this machine?

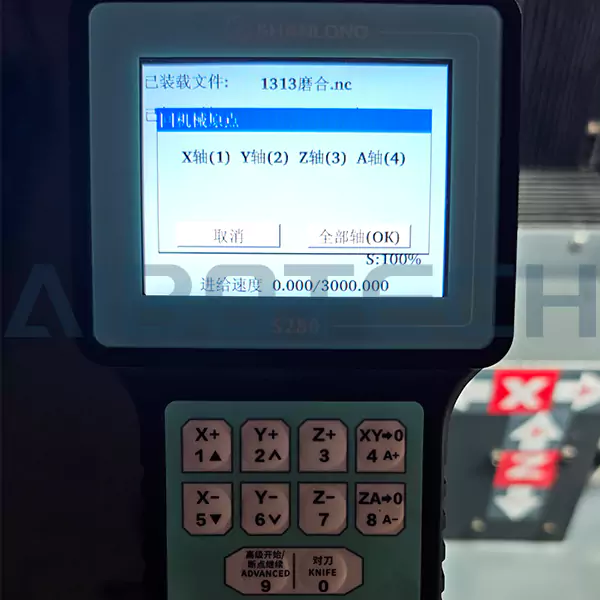

This machine is punched by milling cutter with CNC controler , it can be used for the special hole milling ,like square or oval and normal round hole.You can see some samples we have made, if your hole design is very special, please contact our sales for customization.

What are the advantages of timing belt punching?

1. Enhanced functionality

Installation accessories: Auxiliary devices such as sensors, clamps, suction cups, etc. can be installed by drilling holes to expand the application scenarios of synchronous belts.

Positioning and detection: In automated equipment, punching can be used for photoelectric sensor detection to achieve precise positioning (such as coding tape).

2. Improve heat dissipation performance

Punching can increase air circulation, reduce the temperature rise of the synchronous belt when running at high speed, and extend its service life.

3. Reduce weight

In lightweight design, punching can reduce material usage, reduce inertia, and improve the response speed of high-speed transmission.

4. Improve cleaning ability

In the food, packaging or printing industries, perforated timing belts can be used for suction conveying (such as vacuum suction conveyor belts) to prevent the material from slipping or deflecting.

5. Adapt to special needs

It can be used for electrostatic discharge (such as in the electronics industry) or as a gas path (such as in automated assembly lines).

In medical devices, perforated tape can be used for fluid drainage or ventilation.

6. Easy to maintain and adjust

Some punched holes can easily adjust the tension of the timing belt or replace damaged parts, reducing downtime.

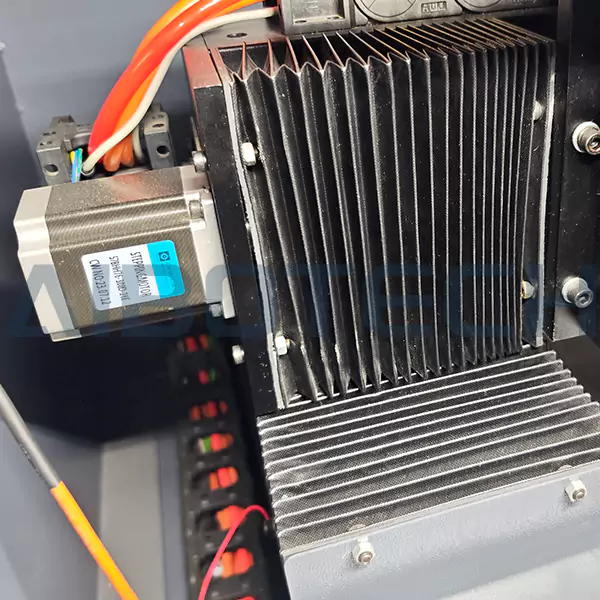

Machine Technical Parameters

| Item Model | DK200 | DK500 |

| Power | 800W | 2.2KW |

| Voltage | 1PH 220V | 1PH 220V |