Machine Details Images

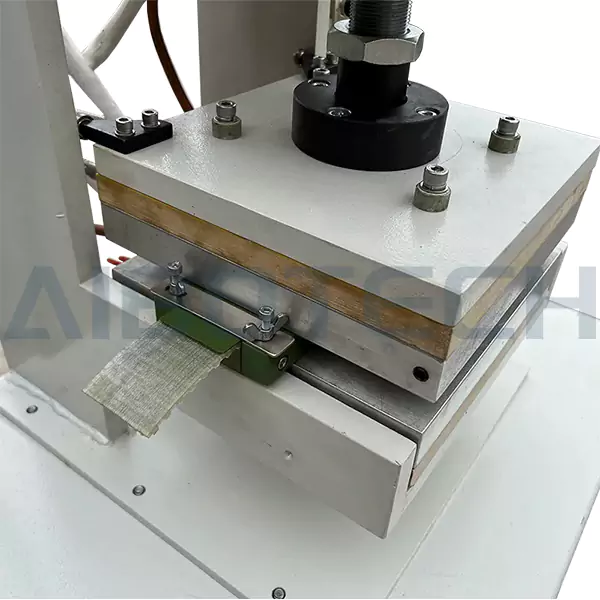

Punching Plate

Punching Plate Heating tube

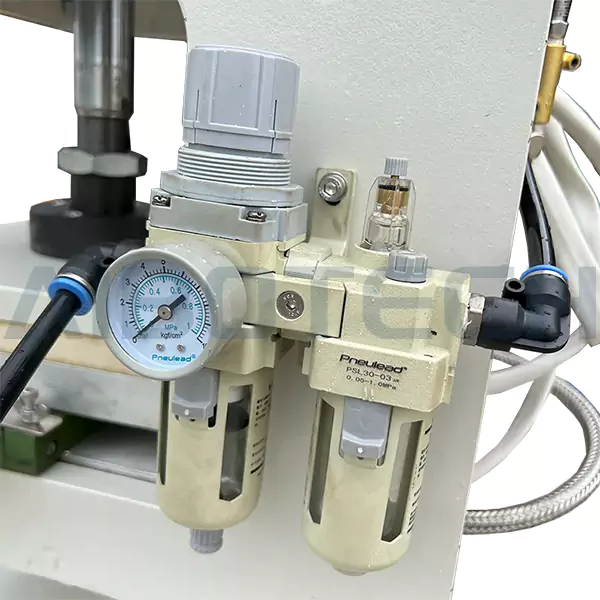

Heating tube Barometer

Barometer input pipe

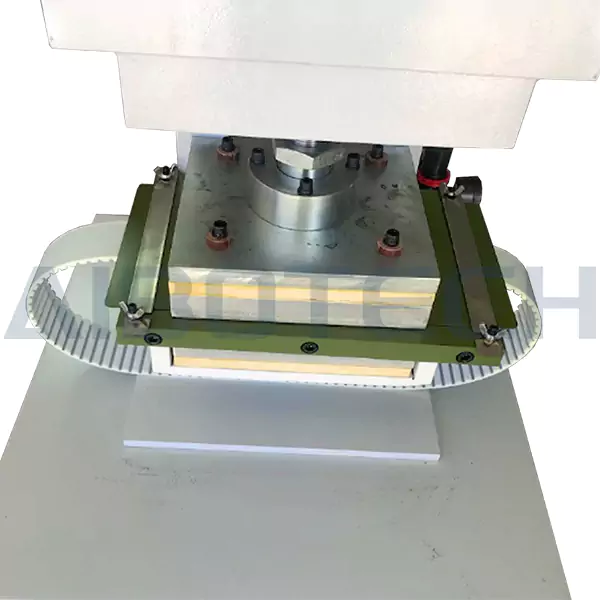

input pipe Heating Timing Belt

Heating Timing Belt Control Panel

Control PanelMachine Accessories Images

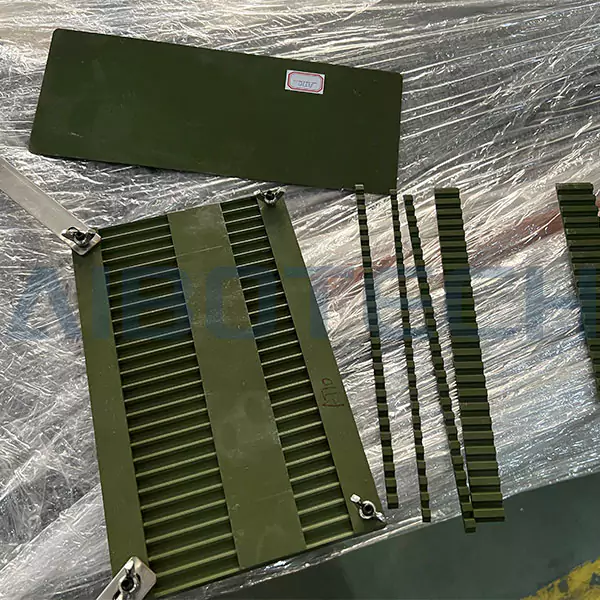

Joint Mould

Joint Mould Joint Mould

Joint Mould Joint Mould

Joint MouldAppreciation of Timing Belts

Machine Videos

PU timing belt jointing machine

Polyurethane synchronous belt is composed of polyurethane as the belt body and steel wire core as the strong layer.

For most opening synchronous belts, there are three more simple joint methods

mechanical joint: generally refers to the use of belt buckle joint. This joint method is convenient and economical, but the efficiency of the joint is low and easy to damage, which has a certain impact on the service life of polyurethane synchronous belt products. In PVC and PVG whole core flame retardant and antistatic polyurethane synchronous belt joints, this joint method is generally used for products below grade 8 belt.

Cold bonded joint: that is, the joint is made with cold bonded adhesive. This joint method is more efficient and economical than mechanical joint, and should have better joint effect. However, in practice, it is not very stable because the process conditions are difficult to master and the quality of adhesive has a great impact on the joint.

Hot vulcanization joint: Polyurethane synchronous belt joint has proved to be the most ideal joint method in many years of actual combat, which can ensure high joint efficiency, but also very stable, long joint life and easy to master. However, there are some disadvantages, such as troublesome process, high cost, long joint time and so on.

Timing belt welding machine is designed for hot vulcanization joint to help you solve above problems .timing belt joint machine is for an endless splice of PU timing belt.

Machine Parameters

| Belt width | Standard 100/150/200mm, other size to be ordered |

| Heating Platen Size | 200*200mm For 150mm width belt |

| Minimum Belt Perimeter | 850mm |

| Voltage | 380V ,3Phase or as optional |

| Power | 7.1KW |

| With Pneumatic Pressure System , Air Pressure | 0.6Mpa |

| Temperatire Range | 50-230 ℃ |

Optional

Timing Belt Jointing Mould (Belt width adjustable).

Self-Circulation Water Cooling System.

Hydraulic Pressure system (Intead of pneumatic pressure system